Step 1

The beginning device development or solution

The whole process begins with a meeting with the customer, where the requirements for functionality, size, wired or wireless interfaces, display unit and other details about the device that the customer needs to design – create are presented. If necessary, a personal inspection of the installation site is planned and the necessary measurements are made in order to specify the various parameters accurately.

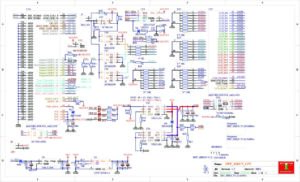

Step 2

Schematic connection design

Based on previous meetings, measurements and consultations, a schematic design of the device is designed – an electronic module, which describes the basic electronic functionality of the device, its interfaces and electrical parameters.